Transformers and cables are important parts of charging piles. Transformers are used for voltage conversion, while cables are responsible for power transmission. When selecting a transformer, you need to consider regional policies and charging pile requirements, and the matching of cables must ensure the normal output of the charger and the safety of the station. Reasonable matching can bring an efficient and safe working environment.

1. Determine the Charging Requirements

a. Charging Power:

Identify the maximum power (in kW) required for your charging station. This could depend on the number of charging points and their power ratings. For example:

- Level 1 (AC): ~1.4 kW (120V, 12A)

- Level 2 (AC): ~7.2 kW (240V, 30A) to 19.2 kW (240V, 80A)

- DC Fast Charging: Up to 350 kW or more

b. Number of Chargers:

Decide how many chargers you will install and their power ratings.

2. Calculate Total Load

For multiple charging stations, calculate the total load:

Total Power (kW) = Number of Chargers × Power per Charger (kW)

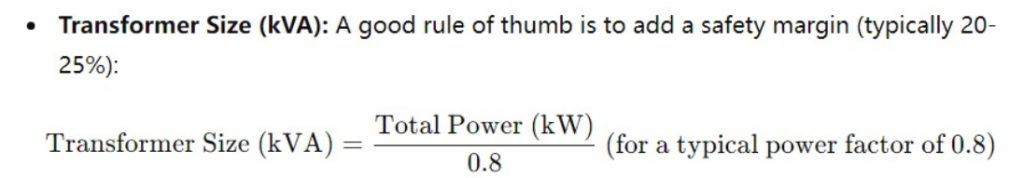

3. Transformer Capacity

The transformer capacity should be slightly higher than the total power requirement to account for losses and future expansion. A common practice is to use a safety factor (e.g., 1.25).

Transformer Capacity (kVA) = Total Power (kW) × Safety Factor or

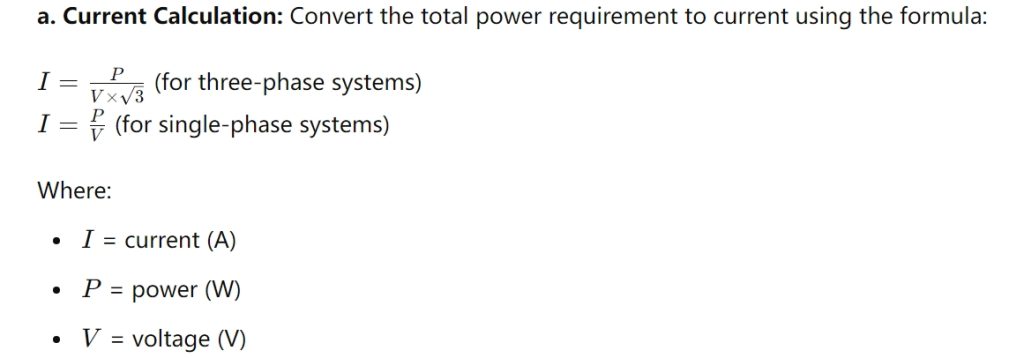

4. Cable Size Calculation

5. Consider Voltage Drop

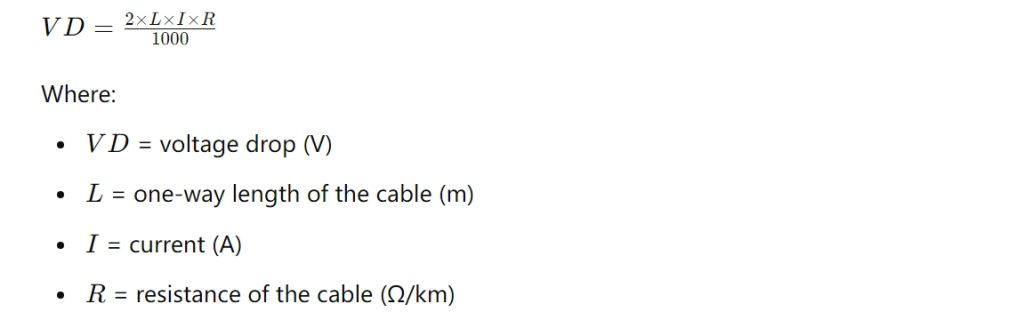

Ensure that the voltage drop does not exceed acceptable limits (usually around 3-5%). Use the following formula to calculate voltage drop:

6. Local Regulations and Standards

Check local electrical codes and standards (like NEC in the US) to ensure compliance with safety regulations, which may dictate certain requirements for transformers and cabling.