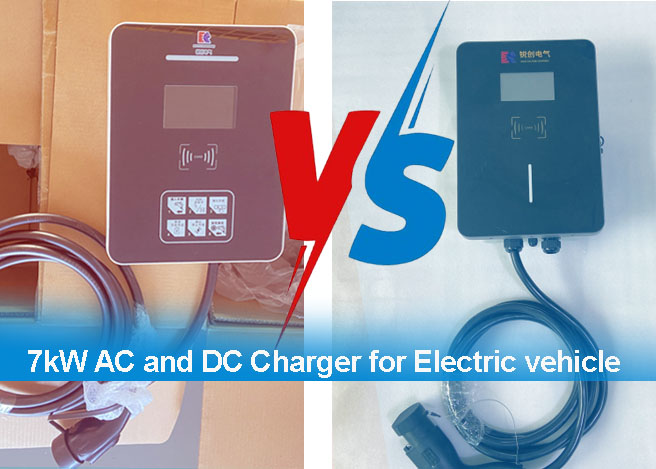

The loss of a EV charger refers to the energy lost in the process of transmitting electrical energy from the charging pile to the electric vehicle. During the EV charging process, electric energy will be lost due to various reasons. These losses mainly include conversion loss of AC to DC, line loss, internal loss of equipment, etc.

To calculate the power loss of an EV charger in general terms, you'll need to follow these steps:

- Determine Input Power (P_in): This is the total power supplied to the EV charger from the electrical source. It is usually given in watts (W) or kilowatts (kW). For example, if your charger is rated at 7 kW, that would be your input power.

- Determine Output Power (P_out): This is the power delivered by the charger to the electric vehicle. This is also given in watts or kilowatts. For instance, if the EV charger is supposed to deliver 6.5 kW to the vehicle, then this is your output power.

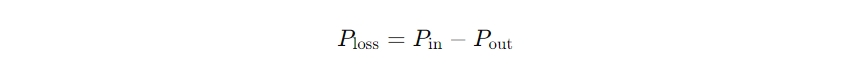

- Calculate Power Loss (P_loss): The power loss can be calculated by subtracting the output power from the input power:

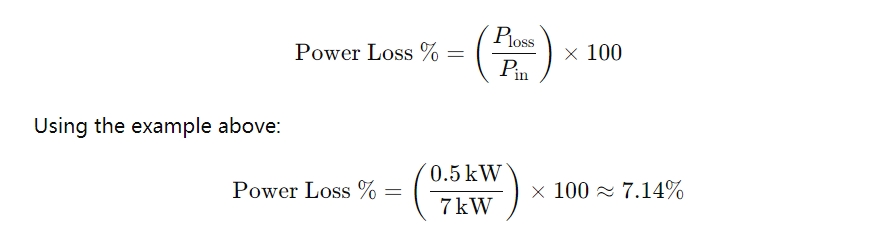

For example, if the input power is 7 kW and the output power is 6.5 kW, then:

Ploss=7 kW−6.5 kW=0.5 kW

- Express Power Loss as a Percentage (Optional): To express power loss as a percentage of the input power, use the following formula:

In practice, power loss can occur due to various factors such as inefficiencies in the electronic components, resistive losses in the circuitry, and heat dissipation. Most modern EV chargers are designed to be quite efficient, but exact loss figures can vary based on the design and condition of the charger.

The power loss of the charging station during the charging process is an important consideration. For DC charging stations, power loss of around 12% is considered normal.

To reduce the power loss of the charging pile, the following measures can be taken:

- Choose a high-efficiency transformer: Choose a transformer with high conversion efficiency

- Use low-resistance wires and connectors: Choose wires and connectors with low resistance materials to reduce resistance losses.

- Reasonably design the cooling system: Ensure that the cooling system of the charging pile can effectively dissipate heat to reduce the temperature of electronic components and improve work efficiency.